iglidur® Q290 – material data

Material data table

| General properties | Unit | iglidur® Q290 | Testing method |

| Density | g/cm³ | 1,27 | |

| Colour | black | ||

| Max. moisture absorption at 23 °C / 50% r.h. | % weight | 3,0 | DIN 53495 |

| Max. water absorption | % weight | 9,3 | |

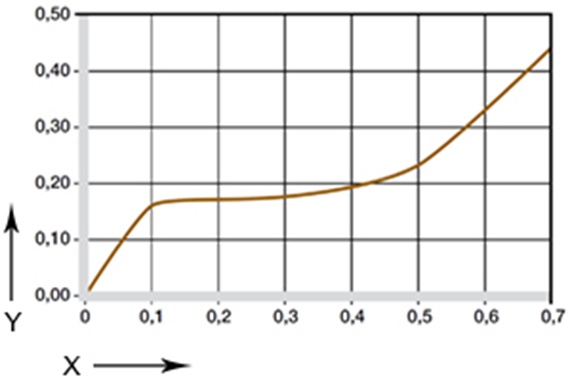

| Coefficient of surface friction, dynamic, against steel | µ | 0,14 - 0,26 | |

| pv value, max. (dry) | MPa x m/s | 0,70 | |

Mechanical properties | |||

| Modulus of elasticity | MPa | 3.074 | DIN 53457 |

| Flexural strength at 20 °C | MPa | 97 | DIN 53452 |

| Compressive strength | MPa | 68 | |

| Recommended max. surface pressure (20 °C) | MPa | 55 | |

| Shore-D hardness | 80 | DIN 53505 | |

Physical and thermal properties | |||

| Max. long-term application temperature | °C | +140 | |

| Max. short-term application temperature | °C | +180 | |

| Lower application temperature | °C | -40 | |

| Heat conductivity | [W/m x K] | 0,24 | ASTM C 177 |

| Coefficient of thermal expansion | [K-1 x 10-5] | 7 | DIN 53752 |

Electrical properties | |||

| Specific contact resistance | Ωcm | > 1012 | DIN IEC 93 |

| Surface resistance | Ω | > 1012 | DIN 53482 |

iglidur® Q290 bearings do not have the highest static load capacity within the iglidur® product range, instead the material shows its strengths at moderate to high dynamic loads: outstanding service life is achieved for rugged pivoting applications, e.g. in agricultural or construction machinery, and especially on "soft" shafts, for both the shafts and bearings!

Mechanical properties

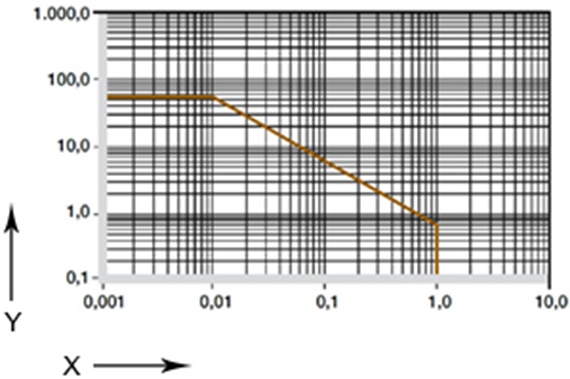

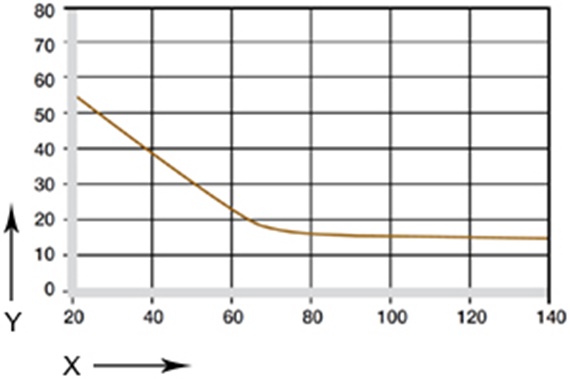

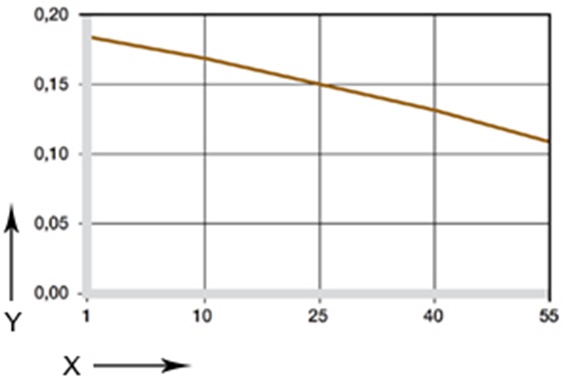

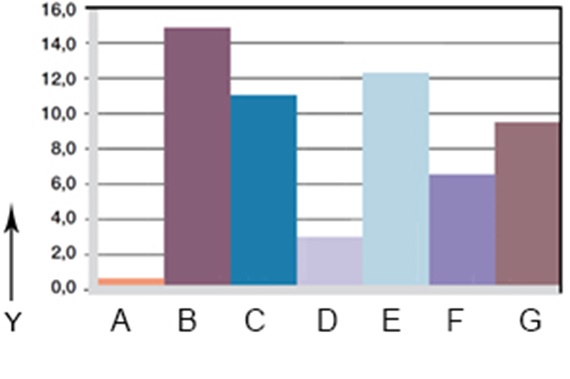

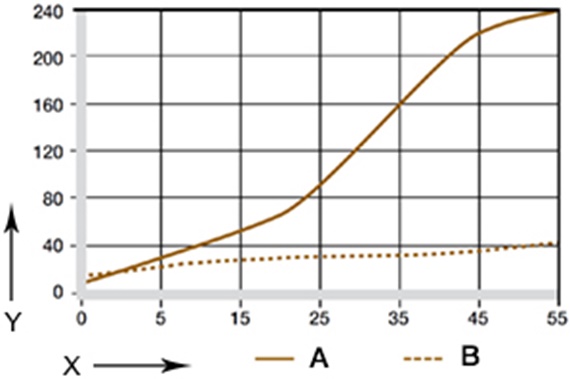

With increasing temperatures, the compressive strength of iglidur® Q290 plain bearings decreases. The diagram 02 shows this inverse relationship. With the short-term permitted application temperature of +180 °C, the permitted surface pressure is still more than 10 MPa. The recommended maximum surface pressure is a mechanical material parameter. No conclusions regarding the tribological properties can be drawn from this.| m/s | Rotating | Oscillating | Linear |

| Continuous | 0,8 | 0,6 | 1 |

| Short-term | 2 | 1,4 | 2 |

Table 02: Maximum surface speeds

Permissible surface speeds

Typical applications for iglidur® Q290 bearings include mid to high-load pivoting movements at comparatively slow speeds. However, relatively high speeds are still attainable. The speeds shown in table 03 are threshold values for low bearing loads. They do not provide any indication of the wear resistance under these parameters.Temperatures

The maximum long-term application temperature of +140 °C enables the use of iglidur® Q290 in, for example, typical applications in the agricultural, commercial vehicle or construction sectors. Starting at an operating temperature of +80 °C, an additional axial safeguard is necessary for the bearing, as a press fit alone is no longer sufficient.

Friction and wear

Please note that a sliding surface with a rough surface finish will increase the friction. The coefficient of friction of iglidur® Q290 also increases as the speed increases.

Shaft materials

Generally, the use of hardened shafts is recommended for higher loads starting at approximately 10 MPa. This is, however, often not the case in practice, especially in connection with corrosion-resistant coating methods. Thus, the iglidur® Q290 material is very influential in such applications.Shaft materials

| Medium | Resistance |

| Alcohol | + to 0 |

| Hydrocarbons | + |

| Greases, oils without additives | + |

| Fuels | + |

| Diluted acids | 0 to - |

| Strong acids | - |

| Diluted alkalines | + |

| Strong alkalines | + to 0 |

All information given at room temperature [+20 °C]

Table 05: Chemical resistance of iglidur® A290

Electrical properties

| Specific contact resistance | > 1012 Ω cm |

| Surface resistance | > 1012 Ω |

Radiation resistance

Plain bearings made from iglidur® Q290 are resistant to radiation up to an intensity of 3 · 102 Gy.UV resistance

iglidur® Q290 bearings have good resistance to UV rays and other weathering effects.Vacuum

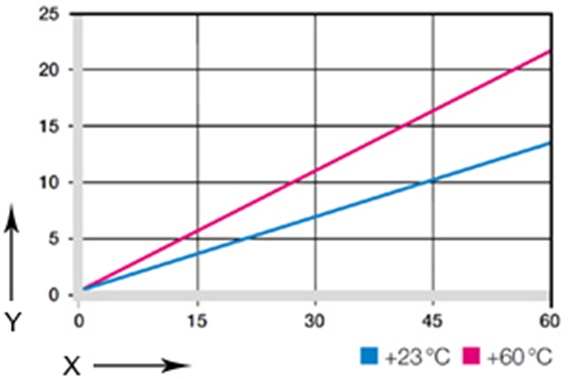

In a vacuum, any moisture content will outgas. Use in a vacuum is possible only to a limited extent.Moisture absorption

Under normal climatic conditions, the moisture absorption of iglidur® Q290 plain bearings is 3.0 % weight. The saturation limit in water is 9.3 % weight.| Diameter d1 [mm] |

Shaft h9 [mm] |

iglidur® A290 D11 [mm] |

Housing H7 [mm] |

| to 3 | 0 - 0,025 | +0,020 +0,080 | 0 +0,010 |

| > 3 bis 6 | 0 - 0,030 | +0,030 +0,105 | 0 +0,012 |

| > 6 bis 10 | 0 - 0,036 | +0,040 +0,130 | 0 +0,015 |

| > 10 bis 18 | 0 - 0,043 | +0,050 +0,160 | 0 +0,018 |

| > 18 bis 30 | 0 - 0,052 | +0,065 +0,195 | 0 +0,021 |

| > 30 bis 50 | 0 - 0,062 | +0,080 +0,240 | 0 +0,025 |

Table 07: Important tolerances for iglidur® Q290 plain bearings according to ISO 3547-1 after being pressed in