Verander van taal :

Duurzame energiekettingen voor portaalkranen

White paper: efficiënte energietoevoersystemen voor kranen in staalfabrieken

De moderne staalproductie vindt plaats in steeds meer geïntegreerde staalfabrieken. Welke technische uitdagingen levert dit op voor de gebruikte transport- en transportsystemen, met name voor de kranen in de staalfabriek? Hoe kan een betrouwbare en efficiënte energievoorziening worden bereikt? Er zijn twee mogelijke oplossingen: Festoons en kabelrups. Welk systeem biedt meer voordelen?

Duurzame producten voor binnenkranen

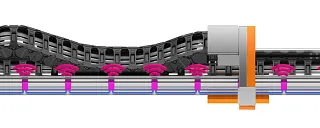

Rendabele kabelrups zonder geleidingsgoot

Energie- en datatransmissie geïnstalleerd in 1 uur

Techniek omhoog

- Energie, gegevens, lucht en vloeistoffen in ÉÉN systeem

- 50 % van de halvloer blijft vrij, geen geleidingsgoot nodig

▼ Kostenbesparing

- 88% kortere installatietijd vergeleken met een conventionele standaardoplossing met geleidingsgoot

- Minder onderhoud en reiniging nodig

In de trog geïntegreerd positiemeetsysteem EC.PP

Het snel en eenvoudig te installeren positiemeetsysteem voor elk kraantype. Voorzie uw kraan van millimeternauwkeurige positiemeting en creëer de optie om andere slimme kunststof producten te integreren, wat de veiligheid en prestaties van het systeem verder verhoogt.

Snel en eenvoudig te installeren

Verhalen over succesvolle toepassingen met binnenkranen

Getest voor echt gebruik in het grootste testlaboratorium in de branche

Dit kan ook interessant voor u zijn

Havenkranen

Contact

Ik beantwoord uw vragen graag persoonlijk!

igus® B.V.+31(0)346 353 932Verstuur een e-mail

Klantenservice en verkoop

Bereikbaarheid: Maandag t/m vrijdag: 8:00 - 17:00 uur

Webshop: 24/7

Chat-service: Maandag t/m vrijdag 8:00 - 17:00 uur