Verander van taal :

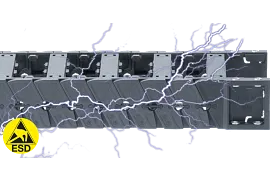

ESD kabelrupsen

E2/000 ESD

Kabelrupsen met twee stukken voor een breed scala aan toepassingen

Serie 1500 ESD

Inwendige hoogte hi: 21mm

Inwendige breedte Bi: 15 - 80mm

Buigradius R: 38 - 145mm

steek: 33,3mm

Serie 2500 ESD

Inwendige hoogte hi: 25mm

Inwendige breedte Bi: 25 - 125mm

Buigradius R: 55 - 175mm

steek: 46mm

Serie 2700 ESD

Inwendige hoogte hi: 35mm

Inwendige breedte Bi: 50 - 125mm

Buigradius R: 63 - 150mm

steek: 56mm

E4.1 ESD

ÉÉN serie voor bijna alle toepassingen

Serie E4.21 ESD

Inwendige hoogte hi: 21mm

Inwendige breedte Bi: 30 - 70mm

Buigradius R: 048 - 100mm

steek: 30,5mm

Serie E4.28 ESD

Inwendige hoogte hi: 28mm

Inwendige breedte Bi: 40 - 125mm

Buigradius R: 055 - 125mm

steek: 46mm

Serie E4.32 ESD

Inwendige hoogte hi: 32mm

Inwendige breedte Bi: 50 - 200mm

Buigradius R: 063 - 250mm

steek: 56mm

Serie E4.42 ESD

Inwendige hoogte hi: 42mm

Inwendige breedte Bi: 50 - 200mm

Buigradius R: 075 - 250mm

steek: 67mm

Serie E4.56 ESD

Inwendige hoogte hi: 56mm

Inwendige breedte Bi: 75 - 300mm

Buigradius R: 135 - 250mm

steek: 91mm

Serie E4.80 ESD

Inwendige hoogte hi: 80mm

Inwendige breedte Bi: 75 - 300mm

Buigradius R: 200 - 300mm

steek: 111mm

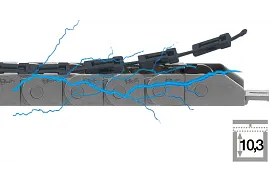

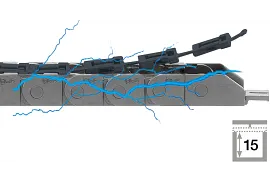

zipper ESD

Snel te openen

Serie 07 ESD

Inwendige hoogte hi: 10,3mm

Inwendige breedte Bi: 10 - 50mm

Buigradius R: 18 - 38mm

steek: 20mm

Serie 09 ESD

Inwendige hoogte hi: 15mm

Inwendige breedte Bi: 16 - 50mm

Buigradius R: 28 - 48mm

steek: 20mm

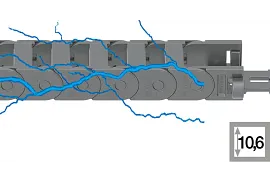

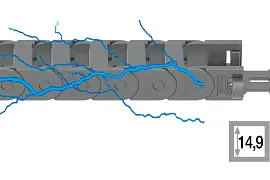

E2 micro ESD

Kleinste afmetingen

Serie E2C.10 ESD

Inwendige hoogte hi: 10,5mm

Inwendige breedte Bi: 16 - 30mm

Buigradius R: 18 - 38mm

steek: 20mm

Serie E2C.15 ESD

Inwendige hoogte hi: 15mm

Inwendige breedte Bi: 16 - 30mm

Buigradius R: 28 - 48mm

steek: 20mm

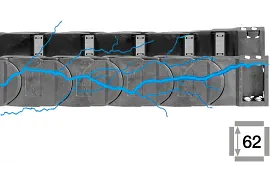

E4/licht ESD

Lichtgewicht, stabiel en kosteneffectief

Serie 14240 ESD

Inwendige hoogte hi: 62mm

Inwendige breedte Bi: 50 - 200mm

Buigradius R: 150 - 250mm

steek: 91mm

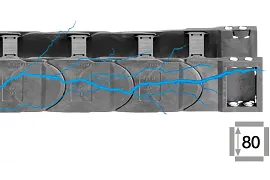

Serie 15050 ESD

Inwendige hoogte hi: 80mm

Inwendige breedte Bi: 75 - 300mm

Buigradius R: 150 - 250mm

steek: 91mm

E6 ESD

Stil vanaf 27dB(A), geringe trilling en geschikt voor cleanrooms

Serie E6.29 ESD

Inwendige hoogte hi: 29mm

Inwendige breedte Bi: 30 - 100mm

Buigradius R: 55 - 150mm

steek: 22mm

Serie E6.40 ESD

Inwendige hoogte hi: 40mm

Inwendige breedte Bi: 40 - 125mm

Buigradius R: 63 - 150mm

steek: 27,8mm

Serie E6.52 ESD

Inwendige hoogte hi: 52mm

Inwendige breedte Bi: 40 - 125mm

Buigradius R: 75 - 150mm

steek: 30mm

triflex® R ESD

Speciaal voor robottoepassingen, gesloten type

Serie TRC.40 ESD

Inwendige hoogte Bi 1: 15mm

Inwendige hoogte Bi 2: 13mm

Buigradius R: 58mm

steek: 13,9mm

Serie TRC.60 ESD

Inwendige hoogte Bi 1: 22,5mm

Inwendige hoogte Bi 2: 19,5mm

Buigradius R: 87mm

steek: 20,4mm

Serie TRC.70 ESD

Inwendige hoogte Bi 1: 28mm

Inwendige hoogte Bi 2: 24mm

Buigradius R: 110mm

steek: 25,6mm

Lintkabel e-skin® vlak ESD

Voor ESD-gevoelige onderdelen in cleanrooms. Geschikt voor cleanrooms tot ISO klasse 1.

Inwendige hoogte hi: 12mm

Uitwendige hoogte ha: 13mm

Aantal kamers: 2 - 6

Kabel diameter: 10mm

ESD-testen in het igus® laboratorium

Contact

Ik beantwoord uw vragen graag persoonlijk!

igus® B.V.+31(0)346 353 932Verstuur een e-mail

Klantenservice en verkoop

Bereikbaarheid: Maandag t/m vrijdag: 8:00 - 17:00 uur

Webshop: 24/7

Chat-service: Maandag t/m vrijdag 8:00 - 17:00 uur