Mijn contactpersoon

igus® B.V.

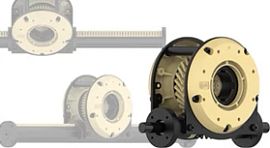

Individuele toepassingen kunnen met het drygear® Apiro® modulaire tandwieloverbrengingssysteem op een modulaire en kosteneffectieve manier worden gerealiseerd. Mogelijke industrieën zijn verpakking, voedsel, medisch en ook vele andere toepassingen zoals

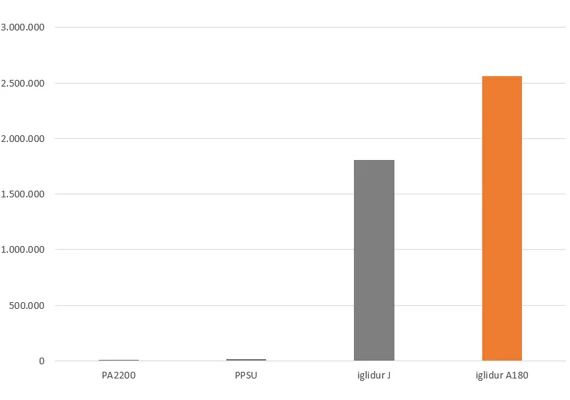

Levensduur in cycli: Apiro-wormwiel van iglidur® A180 op aluminium h.c.

i=32, 20rpm bij 3,5 Nm

Continue kwaliteitstesten in ons eigen testlaboratorium - ook voor klanttoepassingen We testen uw toepassing ook graag om toepassingsscenario's beter te beoordelen.

Maandag t/m vrijdag van 7.00 uur - 20.00 uur.Op zaterdagen van 8.00 uur tot - 12.00 uur.

24h